Chemical Science and Engineering News

Heat Smarter, Not Harder— How Microwaves Make Catalytic Reactions More Efficient

Scientists at Tokyo Institute of Technology (Tokyo Tech) and International Christian University (ICU) demonstrate a synchrotron X-ray spectroscopy-based method by which the local temperatures of metal nanoparticles can be measured under microwaves. This approach provides insight into the role that their temperature has on their catalytic performance and sheds light on how local particle heating using microwaves could become a critical strategy for improving the energy efficiency of catalytic reactions.

Many reactions that we use to produce chemical compounds in food, medical, and industrial fields would not be feasible without the use of catalysts. A catalyst is a substance that, even in small quantities, accelerates the rate of a chemical reaction and sometimes allows it to occur at milder conditions (lower temperature and pressure). A good catalyst can sometimes multiply the throughput of an industrial-scale reactor or shave more than 100 °C off of its operating temperature.

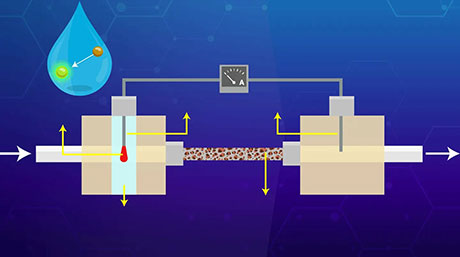

It is no surprise, then, that catalyst research is crucial for making chemical reactions more efficient. One emerging approach that has been observed to provide these benefits is heating the metal nanoparticles in some catalysts directly using microwaves instead of conventional uniform heating techniques. Metal nanoparticles in catalysts interact strongly with microwaves and are believed to be heated selectively. However, scientists have reported conflicting results when using this approach, and understanding the effect that selectively heating the nanoparticles has on chemical reactions is difficult because no methods for measuring their local temperature have been found yet.

Now, scientists at Tokyo Tech led by Prof Yuji Wada tackle this problem and demonstrate a novel approach for measuring the local temperature of platinum nanoparticles in a solid catalyst. Their method, as detailed in their study published in Communications Chemistry![]() , relies on X-ray absorption fine structure (XAFS) spectroscopy, which, as the name implies, provides information on the small local structures of a material using X-rays.

, relies on X-ray absorption fine structure (XAFS) spectroscopy, which, as the name implies, provides information on the small local structures of a material using X-rays.

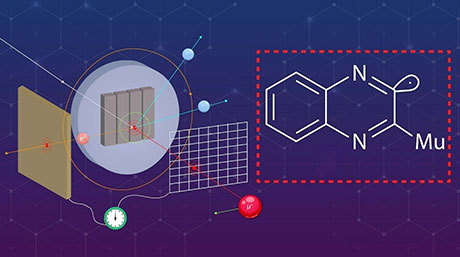

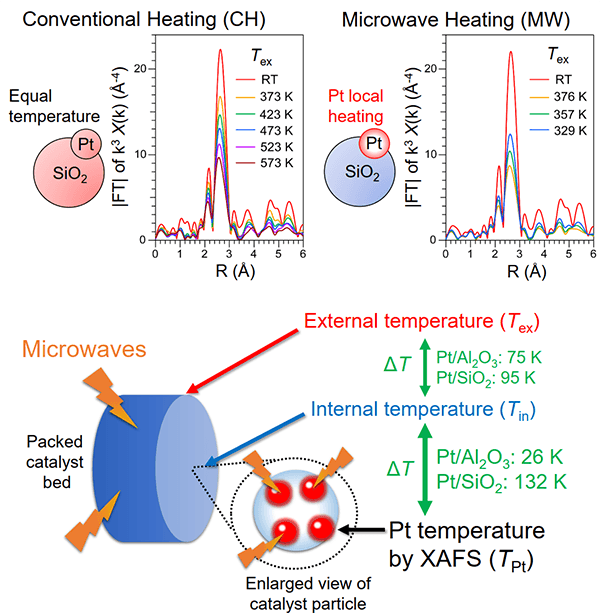

In extended XAFS oscillations, a value called the Debye–Waller factor can be derived. This factor is comprised of two terms; one related to structural disorder, and one related to thermal disorder. If the structure of the catalyst does not change upon microwave heating, any variation in the Debye–Waller factor has to be due to thermal variations. Therefore, XAFS can be used to indirectly measure the temperature of metal nanoparticles, as shown in Figure 1.

Figure 1. Conventional heating versus microwave heating

- (Top) Whereas conventional heating results in a mostly uniform temperature between the platinum nanoparticle and support, microwave heating creates a marked temperature difference. This is revealed by the either gradual or sharp changes in the XAFS spectra as temperature changes. (Bottom) Microwaves selectively heat the metallic nanoparticles in the catalyst and create a temperature gradient that can be indirectly measured via XAFS spectroscopy. In this work, the external and internal temperature differences between nanoparticle and support were determined for two different catalysts, as well as their catalytic performance.

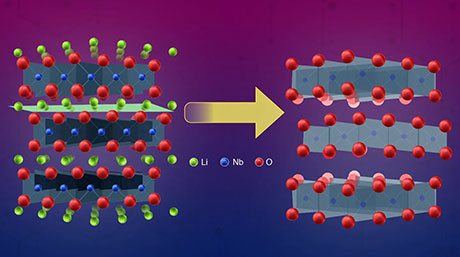

The team of scientists tested this approach in "platinum on alumina" and "platinum on silica" catalysts to find out to what extent microwaves can selectively heat the platinum nanoparticles instead of their supporting material. Microwave heating was found to produce a marked temperature difference between nano particles and support. A series of comparative experiments demonstrated that a higher local temperature of the metal nanoparticles in catalysts is crucial to obtaining higher reaction rates at the same temperature.

Excited about the results, Prof Wada remarks: "This work is the first to present a method for the assessment of the local temperatures of nanoparticles and their effect on catalytic reactions. We conclude that the local heating of platinum nanoparticles is efficient for accelerating chemical reactions that involve platinum itself, presenting a practical approach to obtain a dramatic enhancement in catalytic reactions using microwave heating."

These findings represent a breakthrough for improving our understanding of the role of microwave heating in enhancing catalytic performance. Dr. Tsubaki adds, "Efficient energy concentration at the active sites of catalysts - the metal nanoparticles in this case - should become a critical strategy for exploring microwave chemistry to achieve efficient energy use for reactions and to enable milder conditions for reaction acceleration." This new insight into catalytic processes will hopefully save tons of energy in the long run by making reactors work smarter, not harder.

- Reference

| Authors : | Taishi Ano1, Shuntaro Tsubaki*1,2, Anyue Liu1, Masayuki Matsuhisa1, Satoshi Fujii1,3, Ken Motokura1, Wang-Jae Chun4, and Yuji Wada*1 |

|---|---|

| Title of original paper : | Probing the temperature of supported platinum nanoparticles under microwave irradiation by in situ and operando XAFS |

| Journal : | Communications Chemistry |

| DOI : | 10.1038/s42004-020-0333-y |

| Affiliations : | 1 School of Materials and Chemical Technology, Tokyo Institute of Technology 2 PRESTO, Japan Science and Technology Agency (JST) 3 Department of Information and Communication Systems Engineering, National Institute of Technology Okinawa College 4 Graduate School of Arts and Sciences, International Christian University * Corresponding authors' emails: tsubaki.s.aa@m.titech.ac.jp (S. Tsubaki) , wada.y@mac.titech.ac.jp (Y. Wada) |

- A metal-free, sustainable approach to CO2 reduction | Tokyo Tech News

- A rhodium-based catalyst for making organosilicon using less precious metal | Tokyo Tech News

- Energy-efficient green route to magnesium production | Tokyo Tech News

- Mitsubishi Electric, Tokyo Tech, Ryukoku Univ., Microwave Chemical Develop Microwave Heating System With GaN-amplifier-module Heaters | Tokyo Tech News

- Chemical transformation of carbon dioxide: Copper diphosphine complexes as catalysts for hydrosilylation | Tokyo Tech News

- Motokura-Manaka Laboratory

- Researcher Profile | Tokyo Tech STAR Search - Shuntaro Tsubaki

- Researcher Profile | Tokyo Tech STAR Search - Ken Motokura

- Researcher Profile | Tokyo Tech STAR Search - Yuji Wada

- Institute of Innovative Research, Tokyo Institute of Technology

- Latest Research News

School of Materials and Chemical Technology

—Encompassing the Disciplines of Science—

Information on School of Materials and Chemical Technology inaugurated in April 2016

Further information

Assistant Professor Shuntaro Tsubaki

School of Materials and Chemical Technology,

Tokyo Institute of Technology

Email tsubaki.s.aa@m.titech.ac.jp

Tel +81-3-5734-3735

Specially Appointed Professor Yuji Wada

Institute of Innovative Research,

Tokyo Institute of Technology

Email wada.y@mac.titech.ac.jp

Tel +81-3-5734-2879