Mechanical Engineering News

ODS FeCrAl alloys endure liquid metal flow at 600°C resembling a fusion blanket environment

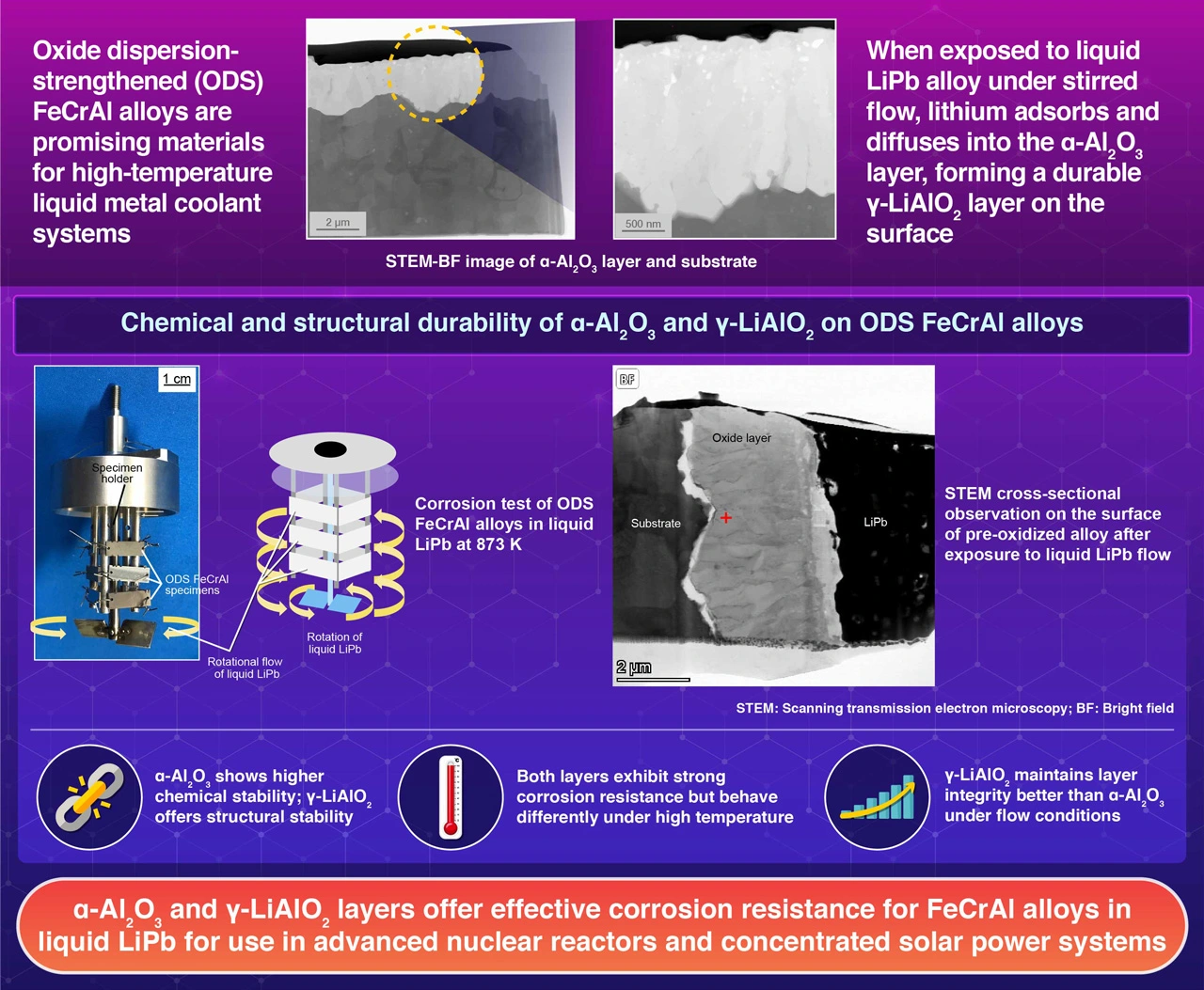

Scientists examined the chemical durability and anti-corrosion potential of oxide layers formed on oxide dispersion-strengthened (ODS) FeCrAl alloys in a liquid metal blanket environment

Researchers explored protective coatings on advanced to resist corrosion in fusion reactors. They tested α-Al2O3 oxide layers on ODS alloys in a high-temperature, flowing lithium-lead environment. Even bare ODS alloys formed a durable γ-LiAlO2 layer in situ, which suppressed further corrosion. The layers exhibited strong adhesion under mechanical stress, making these findings crucial for improving material durability in fusion reactors and high-temperature energy systems.

Exceptional corrosion resistance of ODS FeCrAl oxide dispersion-strengthened alloy in advanced liquid blanket environment for fusion reactors.

Fusion reactors, a promising source of sustainable energy, require advanced materials that can withstand extreme temperatures and corrosive environments created by liquid metal coolants such as lithium and lithium-lead (LiPb) alloy. These coolants are essential in fusion reactors to extract heat and breed tritium, but their corrosive nature threatens the integrity of the structural materials used. LiPb is particularly aggressive, as it has a high concentration of lithium, which reacts with structural materials, causing corrosion and material degradation over time.

ODS FeCrAl alloys, known for their excellent high-temperature strength and corrosion resistance, have been proposed as promising candidates for fusion reactors and other high-temperature applications like concentrated solar power systems. These alloys rely on the formation of protective oxide layers, such as α-Al2O3, which offers stability and durability under high temperatures. However, in a liquid LiPb environment, the chemical interactions between the alloy and the coolant raise concerns about the stability and longevity of these protective layers.

In this view, a team of researchers from Institute of Science Tokyo (Science Tokyo), led by Associate Professor Masatoshi Kondo in collaboration with Yokohama National University, Nippon Nuclear Fuel Development and Department of Research, National Institute for Fusion Science, conducted corrosion tests on oxide layers formed on ODS FeCrAl alloys under prolonged exposure to flowing liquid LiPb at elevated temperatures. Their study was published in the journal Corrosion Science![]() on September 17, 2024.

on September 17, 2024.

The researchers carried out corrosion tests using two types of ODS FeCrAl alloys: SP10 and NF12. The tests were performed under both static and stirred-flow conditions at 873 K to simulate realistic scenarios in fusion reactor coolant systems. They employed advanced metallurgical analysis techniques, including scanning transmission electron microscopy coupled with electron energy loss spectroscopy, to investigate the composition and microstructure of the protective oxide layers formed on the alloy surfaces.

They found that the pre-formed α-Al2O3 layer effectively suppressed initial corrosion but partially transformed into α-/γ-LiAlO2 due to the adsorption of lithium. Interestingly, even without pre-oxidation, the ODS alloys in situ developed a durable γ-LiAlO2 layer, which served as a self-forming protective barrier. Microstructural analysis using advanced electron microscopy revealed the penetration of lithium into the α-Al2O3 layer, leading to the chemical transformation. Despite this, both α-Al2O3 and γ-LiAlO2 layers demonstrated strong resistance to exfoliation. Micro-scratch tests confirmed that these layers adhered strongly to the alloy surface, with minimal degradation, even under high thermal stresses caused by LiPb solidification.

"The lithium-aluminum oxide layer’s durability shows that these alloys could last longer in high-temperature, high-stress settings. This layer serves as a sustainable shield that continues protecting reactor components even after initial wear," explains Kondo.

As nuclear technology evolves, these findings bring us one step closer to developing reactors that can run safely for extended duration, making sustainable energy sources more feasible. "Our findings show that ODS FeCrAl alloys, with their ability to form durable protective layers, could play a vital role in the future"of fusion reactors and other high-temperature power systems,” says Kondo, highlighting the impact of the research study.

Corrosion Resistance of FeCrAl Alloys in Liquid LiPb:

The Protective Role of α-Al2O3 and γ-LiAlO2 Layers

Chemical and structural durability of α-Al2O3 and γ-LiAlO2 layers formed on ODS FeCrAl alloys in liquid lithium lead stirred flow![]()

Kondo et al. (2024) | Corrosion Science | 10.1016/j.corsci.2024.112459

Exploring the corrosion resistance of ODS FeCrAl alloys and the role of protective α-Al2O3 and γ-LiAlO2 layers in liquid LiPb environments

- Reference

| Authors: | Masatoshi Kondo1*, Susumu Hatakeyama2, Naoko Oono-Hori3, Yoshiki Kitamura4, Kan Sakamoto5, Teruya Tanaka6, and Yoshimitsu Hishinuma6 |

|---|---|

| Title: | Chemical and structural durability of α-Al2O3 and γ-LiAlO2 layers formed on ODS FeCrAl alloys in liquid lithium lead stirred flow |

| Journal: | Corrosion Science |

| Affiliations: |

1Institute of Innovative Research, Tokyo Institute of Technology, Japan 2School of Engineering, Tokyo Institute of Technology, Japan 3Faculty of Engineering, Yokohama National University, Japan 4School of Environment and Society, Tokyo Institute of Technology, Japan 5Nippon Nuclear Fuel Development, Japan 6Department of Research, National Institute for Fusion Science, Japan |

| DOI: |

10.1016/j.corsci.2024.112459 |

Related Links

- α-Al2O3 Protective Layer That Sticks to Metal Surface with Functions of an Anchor and Peg | Formerly Tokyo Tech

- Mitigating corrosion by liquid tin could lead to better cooling in fusion reactors | Formerly Tokyo Tech

- Selecting the right structural materials for fusion reactors | Formerly Tokyo Tech

- Research video: Liquid Metal, Shaping the World | Formerly Tokyo Tech

- Sustainable construction using eco-friendly concrete: Press webinar with Assoc. Prof. Masatoshi Kondo | Formerly Tokyo Tech

- Masatoshi Kondo | Researcher Finder - Science Tokyo STAR Search

- Masatoshi KONDO Laboratory

- Laboratory for Zero-Carbon Energy

- Nuclear Engineering Graduate Major|Education|Department of Mechanical Engineering, School of Engineering

- Mechanical Engineering Undergraduate Major|Education|Department of Mechanical Engineering, School of Engineering

- Department of Transdisciplinary Science and Engineering, School of Environment and Society

- Institute of Integrated Research | Science Tokyo organization | About Science Tokyo

- School of Engineering | Science Tokyo organization | About Science Tokyo

- School of Environment and Society | Science Tokyo organization | About Science Tokyo

- Yokohama National University

- National Institute for Fusion Science

- Research

Further Information

Associate Professor Masatoshi Kondo

Laboratory for Zero-Carbon Energy, Institute of Science Tokyo