Materials Science and Engineering News

Boosting Thermopower of Oxides via Artificially laminated Metal/Insulator Heterostructure

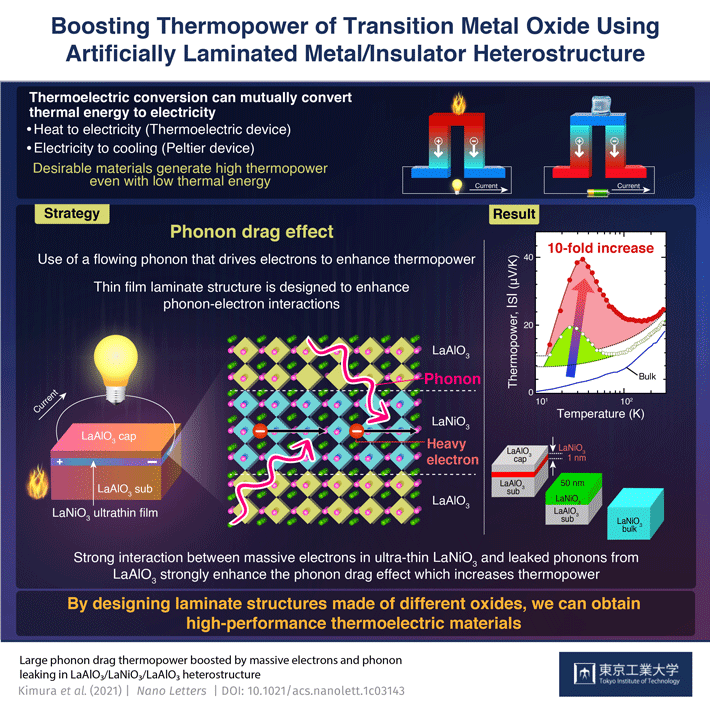

Ultra-thin metal oxide LaNiO3 sandwiched between two insulating layers of LaAlO3 exhibits a 10-fold increase of voltage caused by thermoelectric energy conversion, scientists from Tokyo Tech have demonstrated. This discovery opens up new avenues for development of high-performance thermoelectric materials by designing the laminate structure of different oxides.

Thermoelectric materials have the ability to generate electricity when a temperature difference is applied to them. Conversely, they can also generate a temperature gradient when current is applied to them. Therefore, these materials are expected to find use as power generators of electronic devices and coolers or heaters of temperature control devices. To develop these applications, a thermoelectric material showing high thermoelectric voltage (called thermopower (S)) even on applying low thermal energy is required. However, conventional thermoelectric materials exhibit high conversion efficiency at high temperatures, whereas there are only a few candidates that show high conversion performance at below room temperature.

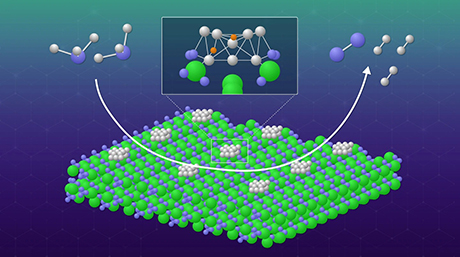

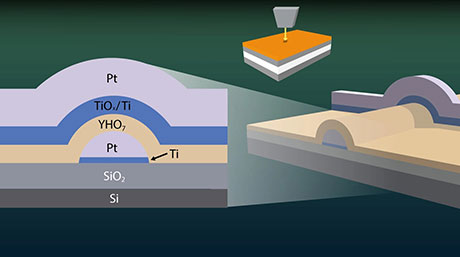

Recently, a team of researchers from Tokyo Tech, led by Associate Professor Takayoshi Katase, developed a new method to significantly enhance S at low temperatures. In a recent paper published in Nano Letters![]() , the team reported an unusually large enhancement of S observed in laminate structures made of an ultra-thin film of the transition metal oxide LaNiO3 sandwiched between two insulating layers of LaAlO3.

, the team reported an unusually large enhancement of S observed in laminate structures made of an ultra-thin film of the transition metal oxide LaNiO3 sandwiched between two insulating layers of LaAlO3.

"We clarified that the unexpected increase in S was not caused by usual thermoelectric phenomenon but by the "phonon-drag effect" arising from the strong interaction of electrons and phonons. If the phonon-drag effect is strong, the flowing phonons can drive the electrons to produce extra thermoelectric voltage when a temperature difference is applied. This phenomenon is not observed in LaNiO3 bulk but appears upon reducing the layer thickness of LaNiO3 film and confining it between insulating LaAlO3 layers," explained Dr. Katase.

By reducing the thickness of LaNiO3 films down to just 1 nm and sandwiching the film between LaAlO3 layers, the team was able to enhance S at least 10-fold. This enhancement was observable for a wide range of temperatures up to 220 K. The experimental analyses revealed that the phonon drag effect originated from enhanced electron-phonon interaction by massive electrons confined in the LaNiO3 layer and the flowing phonons leaking from the upper and lower LaAlO3 layers.

"The findings from this study can be used to explore new high-performance thermoelectric materials by designing the laminate structures of different oxides that can improve energy generation and fuel utilization," concludes Dr. Katase.

- Reference

| Authors : | Masatoshi Kimura1, Xinyi He1, Takayoshi Katase1,2*, Terumasa Tadano3, Jan M. Tomczak4, Makoto Minohara5, Ryotaro Aso6, Hideto Yoshida7, Keisuke Ide1, Shigenori Ueda8,9,10, Hidenori Hiramatsu1,11, Hiroshi Kumigashira12,13, Hideo Hosono11, and Toshio Kamiya1,11* |

|---|---|

| Title of original paper : | Large phonon drag thermopower boosted by massive electrons and phonon leaking in LaAlO3/LaNiO3/LaAlO3 heterostructure |

| Journal : | Nano Letters |

| DOI : | 10.1021/acs.nanolett.1c03143 |

| Affiliations : |

1 Laboratory for Materials and Structures, Institute of Innovative Research, Tokyo Institute of Technology, Japan 2 PRESTO, Japan Science and Technology Agency, Japan 3 National Institute for Materials Science, Japan 4 Institute of Solid State Physics, Vienna University of Technology, Austria 5 Research Institute for Advanced Electronics and Photonics, National Institute of Advanced Industrial Science and Technology, Japan 6 Department of Applied Quantum Physics and Nuclear Engineering, Kyushu University, Japan 7 The Institute of Scientific and Industrial Research, Osaka University, Japan 8 Research Center for Functional Materials, National Institute for Materials Science, Japan 9 Research Center for Advanced Measurement and Characterization, National Institute for Materials Science, Japan 10 Synchrotron X-ray Station at SPring-8, National Institute for Materials Science, Japan 11 Materials Research Center for Element Strategy, Tokyo Institute of Technology, Japan 12 Photon Factory, Institute of Materials Structure Science, High Energy Accelerator Research Organization, Japan 13 Institute of Multidisciplinary Research for Advanced Materials, Tohoku University, Japan |

* Corresponding author's email: katase@mces.titech.ac.jp

- Breaking Trade-Off Problem That Limits Thermoelectric Conversion Efficiency of Waste Heat | Tokyo Tech News

- Giant Electronic Conductivity Change Driven by Artificial Switch of Crystal Dimensionality | Tokyo Tech News

- Multiple Semiconductor Type Switching To Boost Thermoelectric Conversion of Waste Heat | Tokyo Tech News

- Having it Both Ways: A Combined Strategy in Catalyst Design for Suzuki Cross-Couplings | Tokyo Tech News

- Shedding Light on the Development of Efficient Blue-Emitting Semiconductors | Tokyo Tech News

- Filling the Void in Ammonia Synthesis: The Role of Nitrogen Vacancies in Catalysts | Tokyo Tech News

- 2019 Tokyo Tech Challenging Research Award | Tokyo Tech News

- Kamiya-Katase Group

- Takayoshi Katase | Researcher Finder - Tokyo Tech STAR Search

- Toshio Kamiya | Researcher Finder - Tokyo Tech STAR Search

- Hideo Hosono | Researcher Finder - Tokyo Tech STAR Search

- Laboratory for Materials and Structures

- Institute of Innovative Research (IIR)

- Materials Science and Engineering Graduate Major|Education|Department of Materials Science and Engineering, School of Materials and Chemical Technology

- Materials Research Center for Element Strategy (MCES)

- Latest Research News

Further Information

Associate Professor Takayoshi Katase

Institute of Innovative Research,

Tokyo Institute of Technology

Email katase@mces.titech.ac.jp