Civil and Environmental Engineering News

Research Group Initiates First-Ever In-Situ Measurement of Mechanical Properties of Hardened Cement Mortar in Deep Sea

Research Will Contribute to the Establishment of Design Methodologies for Deep-Sea Infrastructure

Ube Industries, Ltd., the Port and Airport Research Institute, Japan Agency for Marine-Earth Science and Technology (JAMSTEC), Tokyo Institute of Technology, and Tokyo University of Marine Science and Technology today announced that a joint research group has established a method for evaluating the mechanical properties of hardened cement mortar and initiated the first-ever in-situ data measurement. The research project aims to contribute to the construction of deep-sea infrastructure. By collecting data on the hydraulic pressure arising inside of hardened cement mortar at a site on the deep-sea floor, the research is expected to yield useful data for the future development of infrastructure materials for deep-sea applications and the establishment of design methodologies for deep-sea structures.

The research is reported in a paper published in the Journal of Advanced Concrete Technology, Volume 19, which was released online on March 26, 2021.

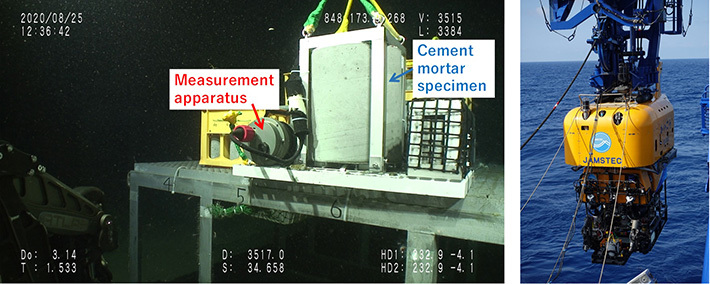

- Left:

- Measurement apparatus next to cement mortar specimen at a water depth of approximately 3,500 meters (Copyrighted image courtesy of JAMSTEC)

- Right:

- Remotely operated vehicle ROV Kaiko Mk-IV, used to install the cement mortar specimen

Research Details

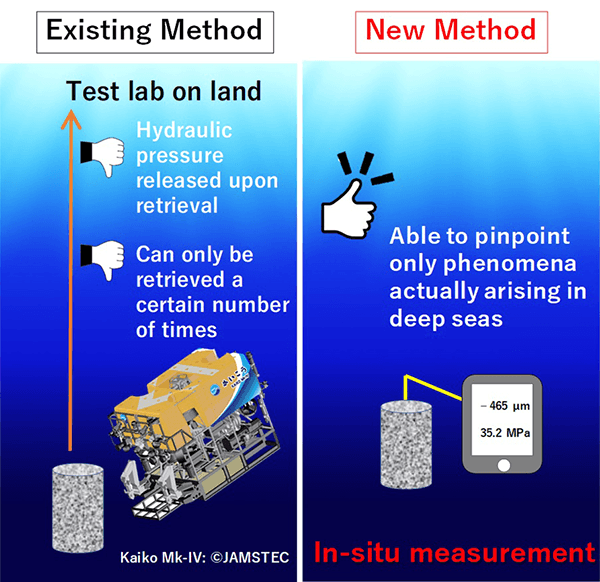

The purpose of the research is to elucidate the mechanical propertiesof hardened cement mortar due to the effects of high hydraulic pressure over both a short and long period of time. Conventionally, a submersible is used to recover the cement mortar specimens deployed on the deep-sea floor, and the changes in the mortar specimen are measured after retrieval However, this method leaves open the possibility that pressure change from deep sea to sea surface on retrieval causes the changes in the cement mortar specimen, potentially preventing an accurate understanding of phenomena arising in the deep sea. Furthermore, testing that utilizes a water tank to simulate the high hydraulic pressure in the deep sea cannot reproduce the phenomena to the degree that they would arise in an actual structure, or the effects of actual currents and attachment of marine organisms.

The researchers established a method that enables continuous in-situ measurement of water pressure and strain arising in a cement mortar specimen on the deep-sea floor. The researchers can then pinpoint only the phenomena actually arising in the deep sea, thereby ensuring accurate data for analysis and interpretation.

In July 2020, the research group deployed a cement mortar specimen and measurement apparatus at a water depth of approximately 3,500 meters in the northeastern rim of the Nankai Trough, located about 70 kilometers from the tip of the Izu Peninsula. The specimen will be recovered in fiscal 2021 and researchers will analyze the data.

Research Background

Japan is the sixth largest maritime nation measured by the area of its economic exclusive zone (EEZ) and territorial waters. Consequently, active ocean utilization is one of the important issues facing Japan. Within Japan's EEZ, deep seas[1] account for a very high proportion of the ocean territory, and in recent years various possibilities for the development of ocean resources has been studied. Other possibilities also are being discussed, which have the potential to create new fields of science and industry. These include ocean energy utilization such as tidal power generation, installation of data centers to take advantage of the sea floor, construction of large neutrino detectors, and deep-sea city concepts.

Utilization of cement, which offers many design possibilities and is highly versatile, is being studied for future construction of ocean infrastructure in deep seas. Cement is manufactured using limestone, which can be entirely sourced in Japan, a country where underground resources are otherwise typically scarce, so it promises the advantage of stable supply as a material.

However, there has been scarcely any evaluation of the impacts of the extreme deep-sea environment on structures that utilize cement. In recent research, the researchers found that hardened cement mortar deteriorates significantly in deep sea*, making it clear that deep-sea infrastructure cannot be constructed using existing knowledge and design methodologies alone. It is becoming important to collect basic data as a step toward constructing deep-sea infrastructure.

Members of Joint Research Group

Ube Industries:

- Keisuke Takahashi, Chief Researcher, Technical Development Center

- Mari Kobayashi, Researcher, Technical Development Center

Port and Airport Research Institute:

- Yuichiro Kawabata, Head of Frontier Technologies for Structures Group, Structural Engineering Field

JAMSTEC:

- Takafumi Kasaya, Group Leader, Research Institute for Marine Resources Utilization Submarine Resources Research Center

- Shun Nomura, Technical Researcher, Department of Mathematical Science and Advanced Technology

Tokyo Institute of Technology:

- Mitsuyasu Iwanami, Professor, Department of Civil and Environmental Engineering

Tokyo University of Marine Science and Technology:

- Toshiro Yamanaka, Professor, Department of Ocean and Environmental Sciences

- Makita Hiroko, Associate Professor, Department of Ocean and Environmental Sciences

- Shinpei Gotoh, Assistant Professor, Department of Marine Electronics and Mechanical Engineering

- Terms

[1] : Deep-sea marine environments are defined as those with a water depth greater than 200 meters. Deep seas are characterized by high hydraulic pressures and low water temperatures. The in-situ measurements discussed in this research are being conducted at a depth of approximately 3,500 meters, where the water pressure is around 350 times greater than atmospheric pressure at sea level.

- Reference

| Authors : | Keisuke Takahashi, Yuichiro Kawabata, Mari Kobayashi, Shinpei Gotoh, Shun Nomura, Takafumi Kasaya, Mitsuyasu Iwanami |

|---|---|

| Title of original paper : | Action of Hydraulic Pressure on Portland Cement Mortars - Current Understanding and Related Progress of the First-Ever In-Situ Deep Sea Tests at a 3515 m Depth |

| Journal : | Journal of Advanced Concrete Technology |

| DOI : | 10.3151/jact.19.226 |

- Infrastructure Management Laboratory (Iwanami Laboratory)

- Researcher Profile | Tokyo Tech STAR Search - Mitsuyasu Iwanami

- Civil Engineering Graduate Major|Education|Department of Civil and Environmental Engineering, School of Environment and Society

- UBE INDUSTRIES,LTD.

- Port and Airport Research Institute

- Japan Agency for Marine-Earth Science and Technology (JAMSTEC)

- Tokyo University of Marine Science and Technology

- Latest Research News

School of Environment and Society

—Creating Science and Technology for Sustainable Environment and Society—

Information on School of Environment and Society inaugurated in April 2016

Further Informaion

Professor Mitsuyasu Iwanami

School of Environment and Society

Email iwanami@cv.titech.ac.jp

Tel +81-3-5734-3194